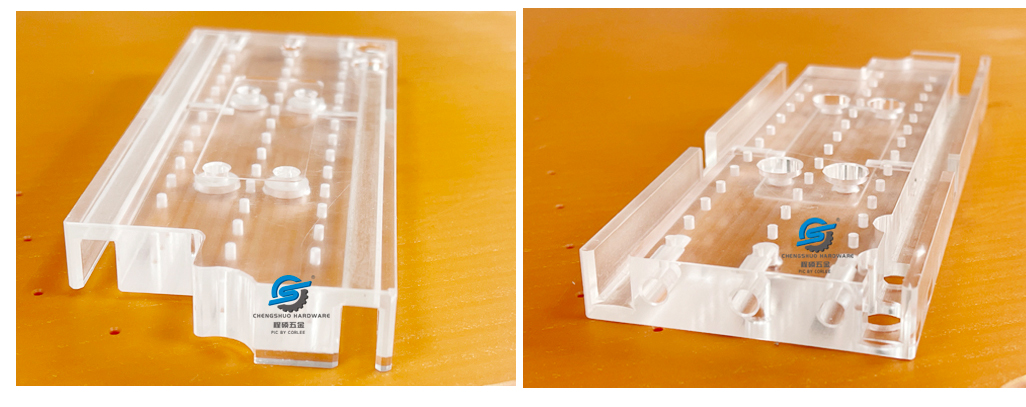

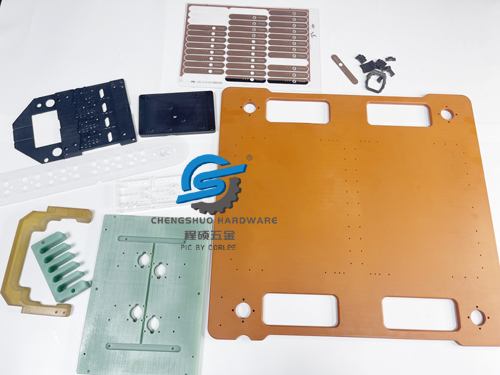

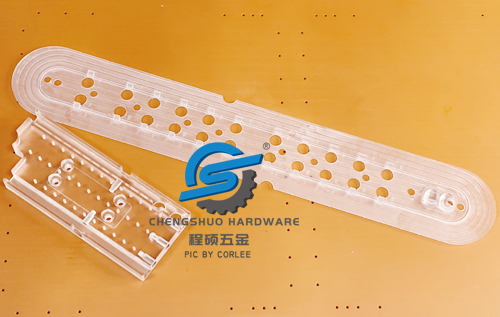

Ukulungiswa kwe-CNC yeemveliso ze-acrylic kunokufezekisa izakhiwo eziyinkimbinkimbi, ukunciphisa iintanda kwizinto ze-acrylic ngexeshaumatshini, kwaye ihlangabezane neemfuno ezichanekileyo eziphezulu zeemveliso.

I-Polymethyl methacrylate (CH3│-[—CH2—C——]—│COOCH3) ineempawu ezilungileyo ezibanzi zoomatshini, ibekwa phakathi kwezona zibalaseleyo phakathi kweeplastiki ngokubanzi. Ukuqina kwayo, ukugoba, kunye namandla oxinzelelo aphezulu kune-polyolefin, kwaye aphezulu kune-polystyrene, i-polyvinyl chloride, njl. Kodwa kwakhona ngcono kancinci kuneepropathi polystyrene.physical.

I-PMMA inamandla amakhulu omatshini: i-molecular mass ye-PMMA imalunga ne-2 yezigidi. Yipolymer emide, kwaye amatyathanga enza imolekyuli athambe kakhulu. Ke ngoko, i-PMMA inamandla aphezulu kwaye ayixhathisi ukolula kunye nefuthe. Amaxesha angama-7 ukuya kwe-18 aphezulu kuneglasi eqhelekileyo.Kukho uhlobo lweglasi yendalo eshushu kwaye yoluliwe, apho amacandelo eemolekyuli acwangciswe ngendlela elungeleleneyo, ephucula kakhulu ukuqina kwento.

I-Acrylic isetyenziswa ngokuqhelekileyo kwishishini ukuvelisa kunye nokwenza iipaneli zepaneli zesixhobo kunye nezigqubuthelo, kunye nezixhobo ezahlukeneyo zotyando kunye nezonyango, izinto zasekhaya: indawo yokuhlambela, imisebenzi yezandla, izithambiso, izibiyeli, i-aquariums, njl.

Xa usebenzisa i-CNC ukucubungula iimveliso ze-acrylic, kufuneka ubeke ingqalelo kula manqaku alandelayo:

1. CNCUyilo lweNkqubo ye-AcrylicUmatshiniIyaqhuba

Kuba acrylic (I-Polymethyl methacrylate, i-PMMA), iinkcukacha zenkqubo yemveliso kufuneka ziyilwe ngokwemilo yemveliso, njengesantya sokutya kwesixhobo kunye nesantya sokujikeleza ngexesha.umatshiniukuqhubekeka. Ngokwemilo yokwenyani yemveliso, inkqubo yokucwangcisa kunye nokuhamba kufuneka iphuculwe ukunciphisa ukonakala ngexesha lokucubungula.

Xa usebenzisa i-CNCumatshiniacrylic, kubaluleke kakhulu ukuseta izinga feed echanekileyo. Ukuba izinga lokutya likhawuleza kakhulu, i-PMMA inokwaphuka ngenxa yoxinzelelo olubi kakhulu. Amazinga okutya okukhawulezayo nawo anokubangela ukuba amalungu aphume kwindawo yokubambisa okanye ashiye ukungafezeki kwicala; Imilinganiselo yesondlo ecothayo inokuvelisa iindawo ezingachanekanga ezinemigangatho erhabaxa, engagqitywanga.

2. Ukukhethwa kweZixhobo kwi-Acrylic Processing kufuneka kube ngokufanelekileyo

Ukucubungula amaphepha e-acrylic kufuna ukusetyenziswa kwezixhobo ezifanelekileyo. Ngokuxhomekeke kwimilo yesixhobo, izixhobo ezisetyenziswa ngokuqhelekileyo ziquka i-end Mills, i-ball nose cutters, i-flat cutters, njl njl. ukucubungula imiphetho yesicatshulwa kunye nemizobo, kwaye umsiki wempumlo webhola ukwimilo ye-arc kwaye ilungele ukucubungula iipateni ezichanekileyo kunye neegophe.

Izinto zemela nazo zibalulekile. Ngokomzekelo, i-high-speed steel cut cut acrylic, kodwa ayiboneleli ngokugqitywa kwendawo. Izixhobo zedayimani zinokuphucula ukugqitywa komphezulu kodwa zibiza kakhulu. I-Carbide ihlala iyinto ekhethiweyo ye-CNC yokusika i-acrylic.

Kwi-CNC machining acrylic, kuyacetyiswa ukuba usebenzise i-engile yokusika irakhi yee-degrees ezi-5 kunye ne-angle eyongezelelweyo yee-2 degrees.

Ukongeza isixhobo ukusika, kufuneka kwakhona ingqalelo ubunzulu ukusika, isantya, njl xa kusetyenzwa iimveliso acrylic ukuqinisekisa ukuba ulwakhiwo izinto acrylic ekrwada ayonakaliswa. I-Acrylic ngokuqhelekileyo yinto ebuthathaka. Ngexesha lokusika kwe-CNC, ukusebenzisa izixhobo ezifanelekileyo kunye nobunzulu obufanelekileyo bokusika kunye nesantya kunokuphepha ukusetyenzwa kwe-scraps okubangelwa ukuqhekeka kwezinto okanye ukutyibilika. Ekusikeni okuqhubekayo, kuyimfuneko ukubamba isantya sangempela sokucubungula kunye nobunzulu besixhobo, kwaye uzame ukuqinisekisa ukuba isakhiwo sezinto eziphathekayo asonakaliswa, njengokuhlukana, ukuqhawula, njl. Ngelo xesha, ingqalelo kufuneka ihlawulwe ekunciphiseni. ubushushu kunye nombane osisigxina ngexesha lokucubungula.

3. Sebenzisa iBit ye-Drill echanekileyo kunye ne-Bevel

Qinisekaii-drill inokudala ngokufanelekileyo imingxuma kwi-acrylic ngokukhetha i-drill material efanelekileyo. I-Carbide lolona khetho lubalaseleyo lokugrumba i-acrylic, kwaye abaninzi abavelisi basebenzisa i-O-groove end mill drill bits eyenzelwe ngokukodwa ukusika kunye nokugrumba i-acrylic. Ukongeza, ii-drill bits kufuneka zigcinwe zibukhali, amasuntswana abuthuntu okubhola aya kuvelisa imiphetho engaphantsi kune-ecocekileyo kwaye ngokulula kunokukhokelela kuxinzelelo lokuqhekeka kunye neentanda.

Xa CNC machining acrylic, kungcono ukusebenzisa bevel nge drill bit. Ukuze uthintele i-drill bit ekonakaliseni amacandelo e-acrylic material, kufuneka ithotywe phantsi kunye ne-slope egudileyo ukukhusela umonakalo kunye nokuqinisekisa indawo egudileyo.

Ngexesha elifanayo, ubunzulu bokusika kunye nolwalathiso kufuneka lubekwe esweni. Ulwalathiso olujikelezayo lwesixhobo se-CNC: ngasekhohlo nasekunene, okanye ngasekunene nangasekhohlo, kufuneka kulungiswe ngokufanelekileyo kwimveliso ukuqinisekisa ukuchaneka kokuphunyezwa kwemveliso kunye nemisebenzi yoyilo.

Ixesha lokuposa: Jan-16-2024