Ukuze kuphunyezwe iiprojekthi zentsimbi ye-hardware, iinjineli zethu ziya kukhetha ngononophelo iinkqubo zokuphumeza iimveliso ezahlukeneyo.

Iindlela eziqhelekileyo zokuqhuba iimveliso zehardware okwangoku ziquka:

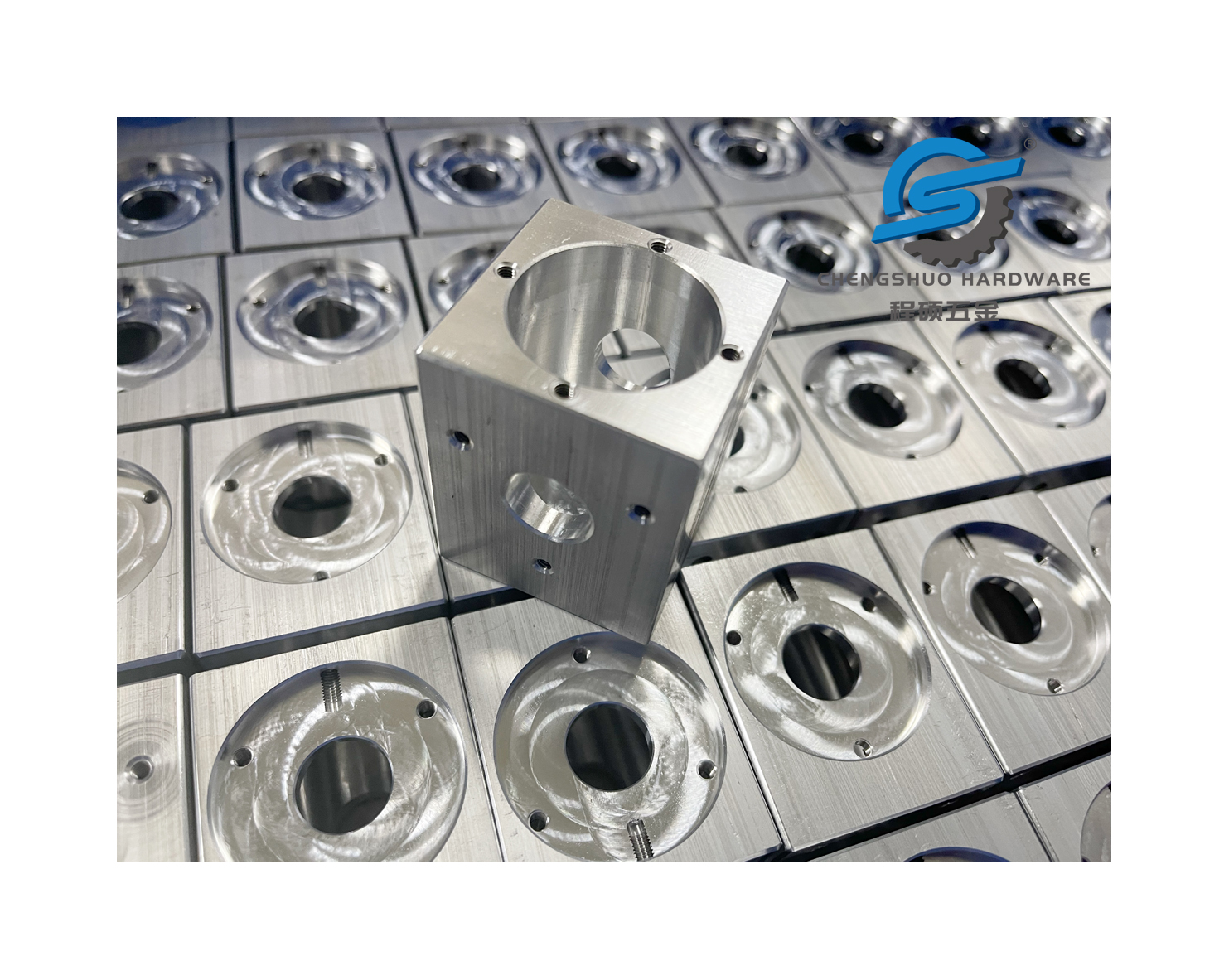

1. CNC machining

Ukujika kwe-CNC, ukugaya, ukubethelwa, i-CNC cutting processing ibhekisa kwinkqubo yokusika iqhekeza lomsebenzi libe kwimilo efunekayo kunye nobukhulu ngesixhobo sokusika. Iinkqubo zokusika eziqhelekileyo ziquka ukujika, ukugaya, ukugaya, njl.

Phakathi kwazo, ukujika kukusetyenziswa kwezixhobo zokusika kwi-lathe ukucubungula amaqhekeza omsebenzi ajikelezayo, anokuvelisa i-diameter eyahlukahlukeneyo, ubude, kunye neengxenye zeshaft yokumila;

Ukugaya kukusetyenziswa kwezixhobo zokusika kumatshini wokusila ukujikeleza kunye nokuhambisa amaqhekeza omsebenzi, anokuvelisa iimilo ezahlukahlukeneyo ezisicaba kunye neendawo ze-convex concave zamacandelo;

Ukugaya kukusetyenziswa kwezixhobo zokusika kumatshini wokubhoboza ukugaya imingxuma kwiindawo zokusebenza, ezinokuvelisa imingxuma yobubanzi obuhlukeneyo kunye nobunzulu.

I-Chengshuo isebenzise iziko lethu lomatshini le-CNC, elinokubonelela ngeenkonzo zokumisa enye kwiimveliso ezichanekileyo ezichanekileyo kunye nezixhobo ezahlukeneyo.

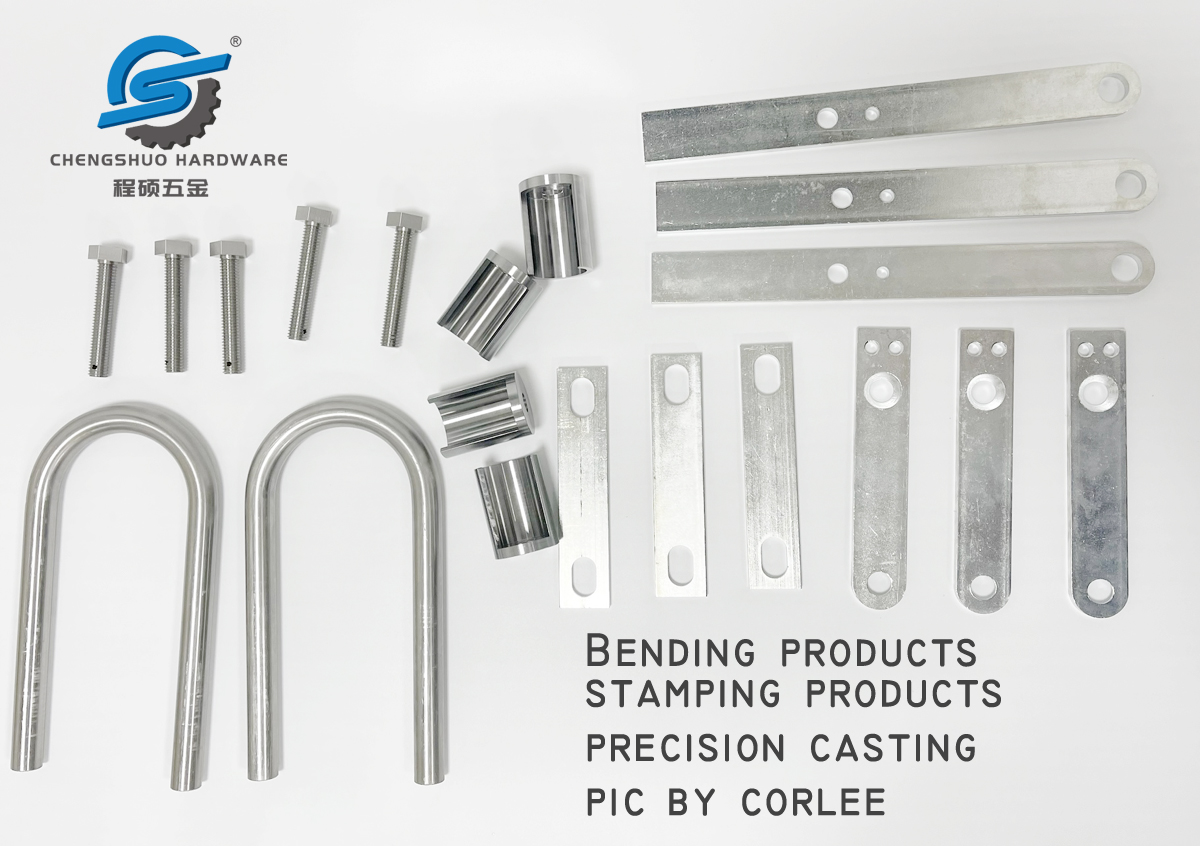

2. Istamping processing - Iziko lokugxiviza

Ukwenziwa kwesitampu kubhekiselele kwinkqubo yokugximfiza amashiti esinyithi kwimo efunwayo ngokufaka isitampu sokungunda. Iinkqubo eziqhelekileyo zokuqhawula ziquka ukusika, ukubetha, ukugoba, njl. Ukubetha kukusebenzisa isikhunta kumatshini wokubhoboza ukubetha ishidi lesinyithi, elinokufumana iimilo ezahlukeneyo kunye nobukhulu bemingxuma; Ukugoba kukusetyenziswa komatshini wokugoba ukugoba amaphepha esinyithi, okukhokelela kwiimilo ezahlukeneyo kunye nee-engile zamalungu.

Stamping die sisixhobo esikhethekileyo inkqubo esetyenziswa ebandayo isitampu processing ukucubungula izinto (intsimbi okanye non-metal) zibe ngamalungu (okanye iimveliso semi-ezigqityiweyo), ebizwa ngokuba stamping ebandayo die (eyaziwa ngokuba stamping ebandayo die)

Ukuhlelwa okuqhelekileyo kwesitampu sokubumba:

(1) Inkqubo enye yokungunda kukungunda okugqibezela inkqubo enye kuphela yokunyathela ngesithombo esinye sokushicilela.

(2) Umngundo odibeneyo unomsebenzi omnye kuphela, kwaye kwi-stroke enye ye-press, i-mold egqiba iinkqubo ezimbini okanye ngaphezulu ze-stamping ngaxeshanye kwi-workstation efanayo.

(3) I-Progressive die (ekwaziwa ngokuba yi-continuous die) ineendawo zokusebenza ezimbini okanye ngaphezulu kwicala lokutyisa izinto ezikrwada. Lungundo olugqibezela iinkqubo ezimbini okanye ngaphezulu zokunyathela kwiindawo zokusebenza ezahlukeneyo kwi-stroke enye yoshicilelo.

(4) I-mold yokudlulisa idibanisa iimpawu zenkqubo enye yokubumba kunye nokubumba okuqhubekayo. Ngokusebenzisa inkqubo yokudlulisa ingalo yerobhothi, imveliso inokudluliselwa ngokukhawuleza ngaphakathi kwesikhunta, iphucula kakhulu ukusebenza kakuhle kwemveliso, ukunciphisa iindleko zokuvelisa, ukugcina iindleko zezinto eziphathekayo, kunye nokuqinisekisa umgangatho ozinzileyo nothembekileyo.

3. Ukwenziwa kweWelding

I-Welding processing ibhekisela kwinkqubo yokudibanisa izinto ezimbini okanye ngaphezulu zetsimbi ngokufudumeza, ukunyibilika, okanye ukuxinzelela. Iinkqubo ze-welding eziqhelekileyo ziquka i-arc welding, i-fluorine arc welding, i-gas welding, njl. Phakathi kwazo, i-arc welding isebenzisa ubushushu be-arc obuveliswa ngumatshini we-welding ukunyibilika kunye nokudibanisa izinto zetsimbi kunye; i-ammonia arc welding isebenzisa ubushushu obuveliswa yi-ammonia arc phantsi kokukhuselwa kwegesi yokukhusela ukunyibilika kunye nokudibanisa izinto zetsimbi; ukuwelda kwegesi kusebenzisa ubushushu belangatye obuveliswa kukutsha kwerhasi ukunyibilika kunye nokudibanisa izinto zetsimbi.

4. Ukugoba ukugoba - iziko lokugoba

Inkqubo yokugoba ibhekisa kwinkqubo yokugoba izinto zetsimbi zibe yimo efunekayo ngomatshini wokugoba. Iinkqubo zokugoba eziqhelekileyo ziquka ukugoba kwe-V, ukugoba u-U, ukugoba u-Z, njl. Ukugoba okumise okwe-U kubhekiselele ekugobeni icwecwe lesinyithi kwi-engile ethile ukwenza imilo emile okwe-U; Ukugoba u-Z yinkqubo yokugoba ishidi lesinyithi kwi-engile ethile ukwenza i-Z-shape

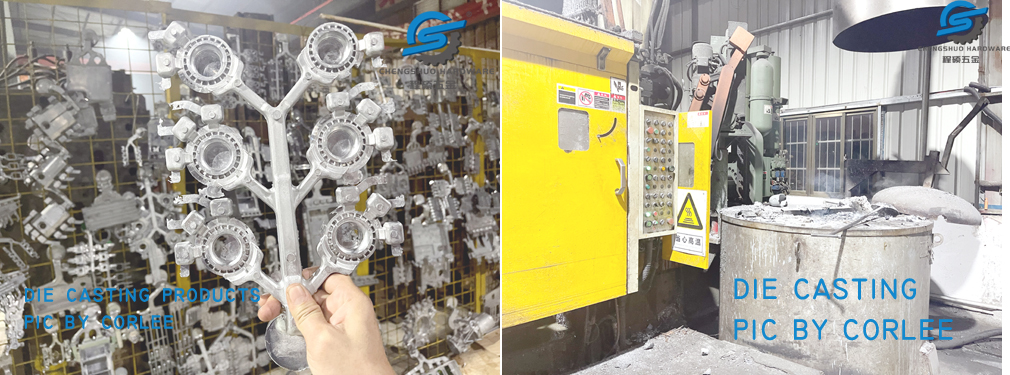

5. I-Die casting processing - Iziko lokuphosa i-Die

Ngokuqhelekileyo isetyenziselwa ukwenza iimveliso zehardware ezirhabaxa. I-Die casting sisishunqulelo sokuphosa uxinzelelo. Yindlela yokuzalisa i-cavity ye-die casting mold kunye ne-liquid okanye i-semi liquid metal kuxinzelelo oluphezulu kunye nokuqina ngokukhawuleza phantsi koxinzelelo lokufumana ukuphosa. Ungundo lokuphosa ukufa olusetyenzisiweyo lubizwa ngokuba yi-die casting mold.

6. Ukulungiswa kweengcingo

I-Chengshuo Hardware inezixhobo zayo zokusika ucingo. Ukusika umgca sisishunqulelo sokusika umgca, ngokubhekisele kwindlela yokucubungula. Iphuhliswe ngesiseko sokukhutshwa kombane kunye nokubhobhoza ukwenza. Yindlela yokucubungula esebenzisa iingcingo zesinyithi ezihambayo (i-molybdenum wire, i-copper wire, okanye i-alloy wire) njengeingcingo ze-electrode, kwaye ivelise amaqondo obushushu aphezulu ngokukhupha umbane phakathi kweengcingo ze-electrode kunye ne-workpiece, ebangela ukuba isinyithi sinyibilike okanye sibe ngumphunga. ukusika i-seams, kwaye ngaloo ndlela ukusika iindawo.

Emva kokucutshungulwa okuhlukeneyo, imveliso ifumana unyango olwahlukeneyo lomphezulu.

Ukunyangwa komphezulu kubhekiselele kwinkqubo yokucoca umphezulu, ukususwa komhlwa, ukunqanda ukubola, ukutshiza kunye nolunye unyango lwezixhobo zehardware. Unyango oluqhelekileyo lomphezulu lubandakanya ukukha, i-electroplating, ukutshiza, njl. Phakathi kwabo, ukuhlamba i-asidi kukusetyenziswa kwezisombululo ze-acidic ukubola kunye nokucoca umphezulu wamacandelo e-hardware, ukususa i-oxides kunye nokungcola phezu komhlaba. I-Electroplating kukusetyenziswa kwe-electrolysis ukufaka i-ion zetsimbi kumphezulu wamacandelo e-hardware ukwenza ifilimu yokukhusela kunye nokuphucula ukuxhathisa ukubola; Ukutshiza kukusetyenziswa kwezixhobo zokutshiza ukutshiza ipeyinti ngokulinganayo kumphezulu wezixhobo zehardware, ukwenza ifilimu ekhuselayo ukukhulisa ubuhle kunye nokumelana nemozulu.

Ixesha lokuposa: Dec-13-2023