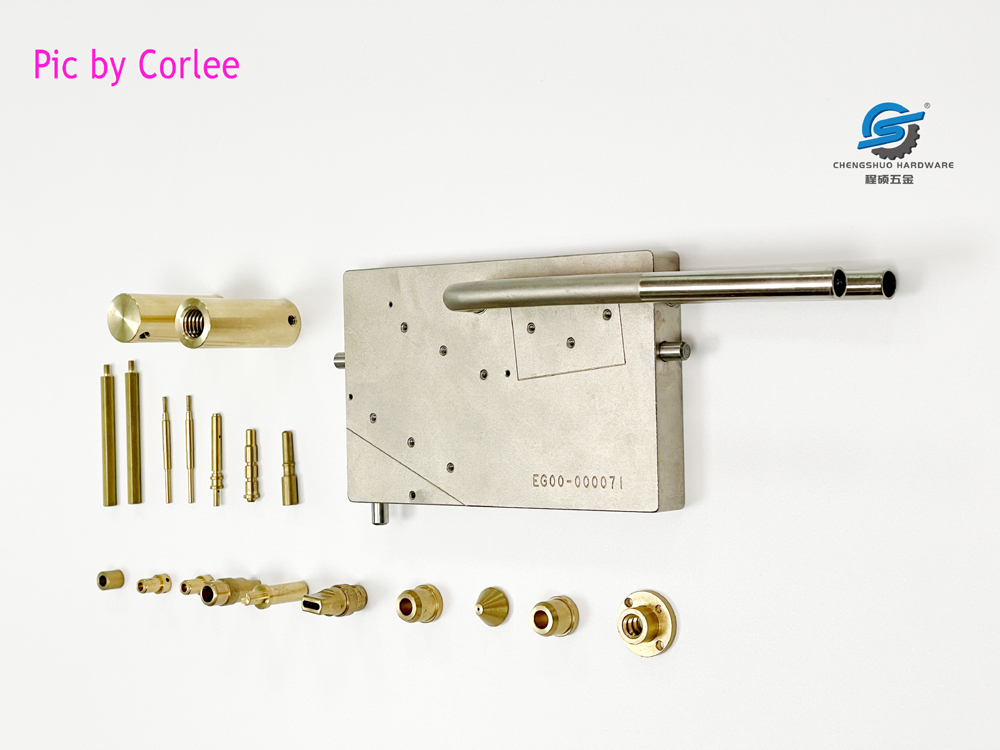

Amalungu eCopper CNC machining anokuba nokufomeka okuhle kuzo zombini iinkqubo zomatshini ezibandayo kunye nezishushu. Ukongeza, uNjinelis kwiChengsnawe haveamava atyebileyoskunyango olungaphezulu lweemveliso zobhedu kunye nezixhobo.

Ngokubanzi, uninzi lwezixhobo zobhedu kunye neenxalenye zinokusebenza kakuhle, ukudumba, kunye namandla empembelelo, kunye nokuhanjiswa okuphezulu kwe-thermal, ukuhanjiswa, ukuxhathisa ukubola, kunye nokumelana nokunxiba.

Amanyathelo for Brass / Copper CNC machining

1. Khetha echanekileyoubhedu/ibakala lobhedu

Phambi CNC copper processing, kufuneka ukhethe ibakala lobhedu oluchanekileyo ukuba yeyona ifanelekileyo yakhoiimveliso' isicelo. Umzekelo, ukukhetha ubhedu olusulungekileyo ukwenza amalungu omatshini akufanelekanga kwaye kuyabiza. Ngoko ke, kulula ukusika ubhedu kunokusebenza kakuhle kwaye yinto efanelekileyo kakhulu. Ukongeza, nabo baneendleko ezifanelekileyo.Kufunekajonga umsebenzi ofunekayo weubhedu/iindawo zethusi ukukhetha ibakala machining ubhedu oluchanekileyo.

2. Uyilo lokuVeliswa (DFM)

Ngaphambi kokucubungulaubhedu/ubhedu,Iinjineli zoomatshini zaseChengshuo zifunakananjalo baqonde iimfuno zoyilo kunye neenkcukacha. Oku kuya kunceda ukufezekisa imisebenzi efunekayo yobheduubheduiinxalenye. Umgaqo wobhontsi kukusebenzisa kunye nokugcina ubukhulu bodonga obuyi-0.5 millimeters ukwenza ubhedu oluhonjiswe ngobuhle./ubheduiinxalenye.

3.Misela ireyithi yokutya efanelekileyo

Isantya sokutya sisantya apho isixhobo sokusika sidibana nomsebenzi. Izinga lokutya elichanekileyo kufuneka libekwe phambi kokuba kucutshungulwe iindawo zethusi, njengoko kuchaphazela umgangatho, ubomi benkonzo, kunye nokuguda komphezulu kwamalungu obhedu. Ukongeza, ubhedu/ubheduine-conductivity ekhawulezayo ye-thermal, kwaye izinga eliphezulu lokutya liya kwandisa ukunxiba kwesixhobo.

4. Khetha isixhobo esichanekileyo

Izinto ezininzi zobhedu zinenkqubo eyahlukileyo kunye nokuqina. Ngoko ke, kubalulekile ukuba ukhethe izixhobo ezifanelekileyo zokulungiswa kweengxenye zobhedu, ezinceda ukuthintela iingxaki ezifana nokunxiba izixhobo kunye nokuvala i-chip.

Unyango lwesithuba semveliso yobhedu eqhelekileyo ye-CNC

Iindlela zonyango eziqhelekileyo zobhedu/ubheduiimveliso emva CNC machining ziquka:

1. Electrolytic polishing

I-Electrolytic polishing ikwanceda ekuphuculeni ukumelana nokubola kobhedu olugqityiweyo/ubheduiinxalenye.Ngexesha lenkqubo yokupholisa i-electrolytic, uluhlu oluncinci lwezinto eziphathekayo luya kususwa kwindawo yobhedu. Ububanzi besi sixhobo ngokuqhelekileyo buphakathi kwe-0.0025 millimeters kunye ne-0.063 millimeters, kwaye le ndlela yonyango emva konyango inceda ukwenza ubuso bobhedu obugqityiweyo./ubheduiindawo ezigudileyo kwaye zibengezela ngakumbi, njenge-nickel plating.

2. Electroplating

I-Electroplating inceda ukwandisa ubomi benkonzo yobhedu/ubheduiinxalenye, kunye nobhedu electroplating inceda ngakumbi ukukhusela umphezulu wangaphandle iindawo zethusi ukusuka oxidation, ukunyanga ngaphandle kokonakalisa conductivity kunye conductivity thermal yentsimbi.

3. Ukuqhunyiswa kwesanti

Le ndlela emva kokulungiswa inceda ukufihla iziphene kubhedu/ubheduiinxalenye. Ukongeza, ukuqhushumba kwesanti kunokwenza umphezulu womelele ngakumbi, ube matte, kwaye uthambile.

Ixesha lokuposa: Dec-06-2023